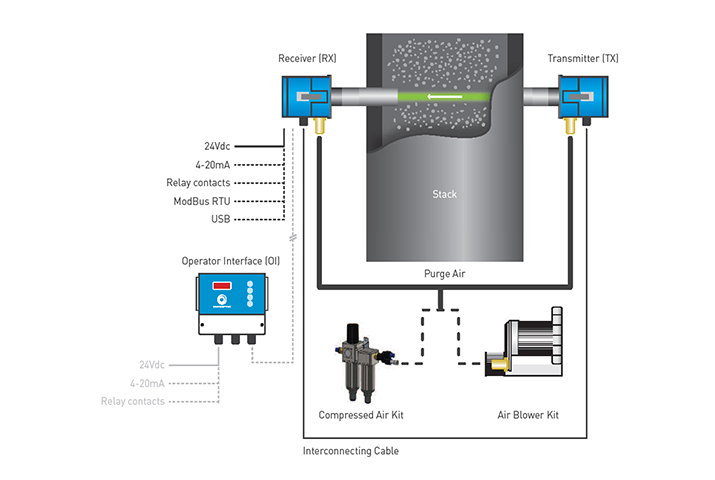

The DSL-240 uses the innovative Dynamic Detection Principle (DDP) in which a light beam emitted from the Transmitter passes across the stack to the Receiver, which measures fluctuations in the intensity of the received light. Increased particulate density in the stack causes the amplitude of these fluctuations to increase. When calibrated against standard reference measurements, the amplitude of this signal relates directly to the particulate concentration in the stack, and this can be presented as a reading in mg/m³.

The DSL-240 has no moving parts, is of rugged design and has an excellent reliability record. Regular maintenance simply involves cleaning the TX and RX lenses, which are easily accessible due to our latched head design. Both the TX and RX heads are supplied with an air purge body, which when connected to a high volume source of clean air, keeps the contaminated stack gas away for the lens surfaces. An Aluminium air purge body is available for use on standard installations and a more advanced Stainless Steel air purge body is available for more demanding installations.

Advantage:

- Innovative Dynamic Detection Principle (DDP) measurement technique

- Measurement reading as mg/m3

- Internal electronic calibration check facility

- Rugged 316L stainless steel construction

- Immune to gradual reductions in absolute intensity of the light signal so less susceptible to drift

- Free utility software for PC based setup, control, and data logging

- Optional Operator Interface with different mounting configurations