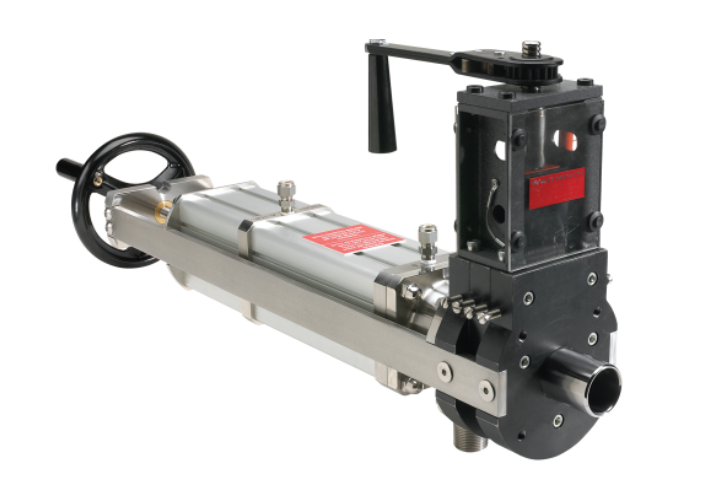

The Sentry ISOLOK SAL-Q sampler employs the industry-proven Delta double block and bleed, ANSI-rated knife gate valve to isolate the sampler from the process line when the sampler needs servicing.

The sampler actuator is manually inserted into and through the knife gate valve by simply turning a hand wheel, and it then is bolted onto the gate valve.

The sampler is operated by standard plant compressed air and controlled by either the plant DCS/PLC or a Sentry time-based sampler controller to suit the application. The ISOLOK SAL-Q sampler is easy to maintain, as the plunger extends to provide access to wrench flats and seals. It also features internal wear sleeve and process seals that are easily replaceable in the field.

Advantage:

- Collects up to 25 cc sample volume per cycle

- Handles solids up to 1/4″ (5 mm)

- Accommodates process lines up to 400 psi (27.5 bar) pressure

- Rugged Stainless Steel construction

- Specialized alloys and seals available on request

- Controllers and remote operating modules available in a variety of configurations