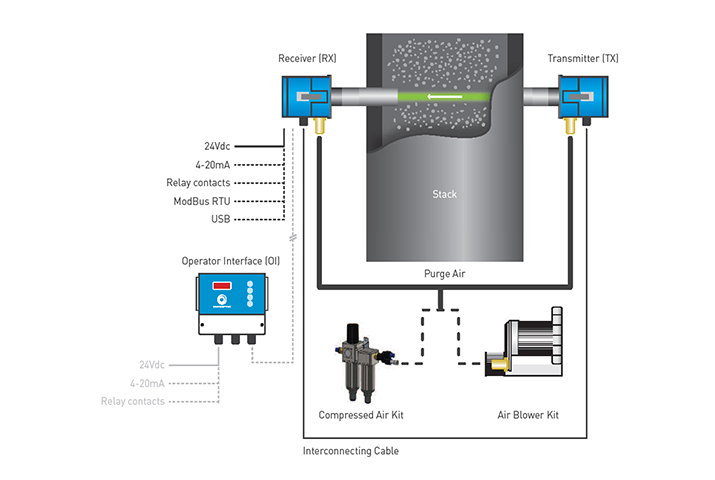

The DSL-230 uses the standard single pass transmission measurement technique, with Transmitter/Receiver

arrangement. A light beam emitted from the Transmitter passes across the stack to a Receiver, which measures the intensity of the received light. Increased particulate or smoke density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. When calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m3.

The DSL-230 has no moving parts, is of rugged design and has an excellent reliability record. Regular

maintenance simply involves cleaning the TX and RX lenses, which are easily accessible due to our latched head design. Both the TX and RX heads are supplied with an air purge body, which when connected to a high volume source of clean air, keeps the contaminated stack gas away for the lens surfaces. An Aluminium air purge body is available for use on standard installations and a more advanced Stainless Steel air purge body is available for more demanding installations.

Advantage:

- Ideal for monitoring particulate levels in exhaust gas of industrial combustion or air filtration processes

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Simple calibration,commissioning

- Rugged 316L stainless steel construction.

- Free utility software for PC based, setup, control, and data logging

- Optional Operator Interface with different mounting configurations