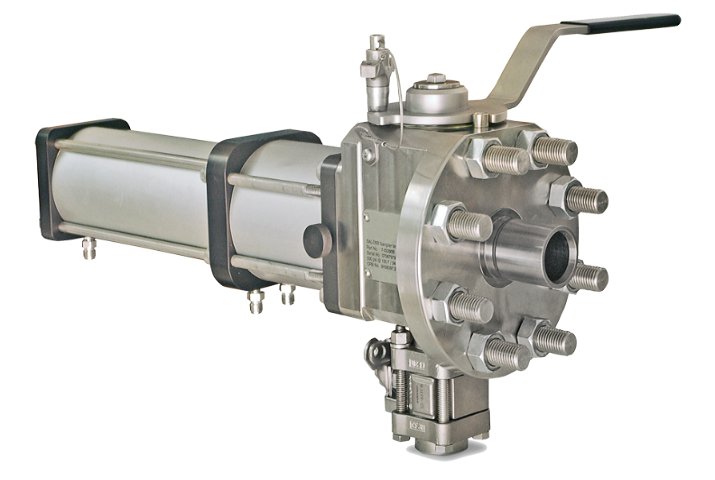

The ISOLOK SAL-DBB sampler offers the best in operator protection, with the ability to be fully isolated from the process prior to the removal of any bolts. To isolate, a single movement of a quarter-turn valve is all that is required. The sampler is designed with a large bleed port to alleviate plugging and for added operator protection.

The ISOLOK SAL-DBB sampler features a 300# ANSI type design for high pressure requirements. This sampler adapts to existing ISOLOK SAL-B line adapters, making it easy to install into existing sample points. Plunger life is increased due to short actuation length and dwell times.

Less wear on seals means less maintenance. When maintenance is required, the removed assembly is lightweight and compact. No special tools are needed, and the sampler bolts are easily accessible for installation or removal. Plunger seal replacement easily can be done in the field without disassembling the entire sampler.

Advantage:

- Double block and bleed sampling valve for operator safety

- Standard 300# class rated; can meet highest pressure requirements

- Lightweight – weight of removed assembly is approximately 18 lb (8 kg)

- Patented “park position” feature

- Disassembly of cylinder assembly is not required to change plunger seals

- Easy to maintain and service in the field – plunger extends to provide access to seals

- Adapts to existing SAL adapter flanges making it easy to install into existing sample points

- Large bleed port design allows for better visual verification for safety & alleviates plugging

- Options include port closures, different container types, sampler enclosures (with or without heater), sample heating or refrigeration, and optional materials of construction and seal choices